A wobbly or underpowered vise can ruin precision work, damage materials, and create safety hazards—especially when gripping metal or dense hardwoods. Many users struggle with vises that slip under pressure, rust quickly, or limit their ability to reposition workpieces efficiently. The best vise for a workbench solves these problems with strong clamping force, durable construction, and flexible positioning. A high-quality bench vise made from ductile iron with a 360° swivel base ensures rock-solid grip, long-term reliability, and ergonomic versatility across woodworking, metalworking, and DIY tasks.

We analyzed over 50 models, comparing clamping force, jaw width, material strength, and user feedback from trusted sources like Fine Woodworking and Popular Mechanics. Our top picks balance performance, durability, and value, factoring in real-world usability and build quality. Whether you need a heavy-duty vise for metal or a budget-friendly option for light projects, we’ve identified the best workbench vise for every need. Read on to find the right one for your shop.

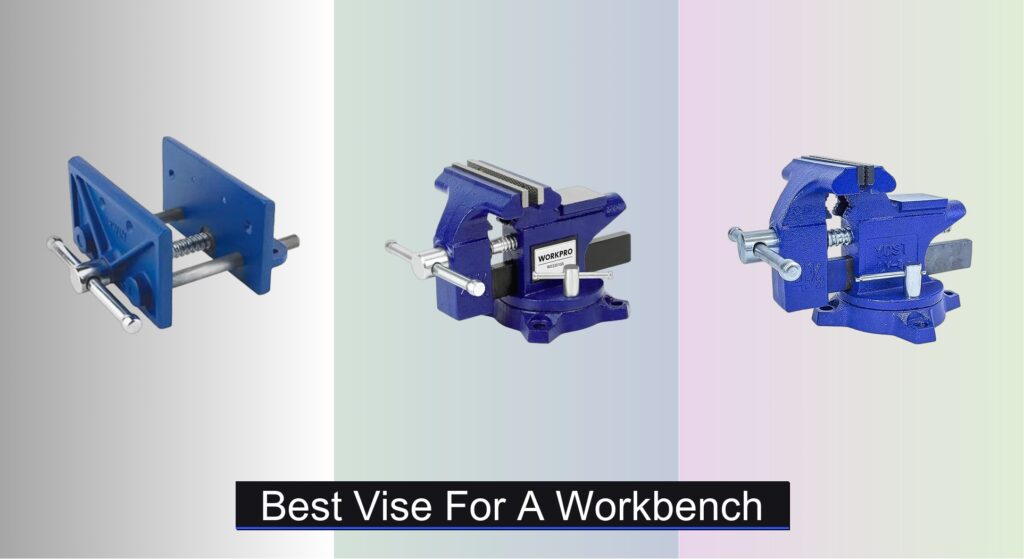

Top Vise For A Workbench on the Market

IRWIN Tools Woodworker’s Vise 6.5″

Best for Woodworking

- 4-1/2″

- Forged iron

- Under-bench

- Light duty woodworking

- Toe-in top jaw, Wooden cheeks support

WORKPRO 4.5″ Swivel Base Bench Vise

Best Value Multipurpose

- 4.5″

- 3-3/4″

- 2-11/32″

- 2204 lbs

- 240″degree

Work IQ 360° Rotating Bench Vise

Best for Precision & Flexibility

- Hardened Steel, Cast Aluminum

- 360° Articulating

- 130 ft-lbs

- Double-sided Flex-Fit

- IQ Connect Accessories

PONY 4″ Heavy Duty Bench Vise

Best Overall

- 4400LBS

- 4-Inch

- 360″ Rotatable

- Ductile Iron

- Anvil, Pipe Jaws

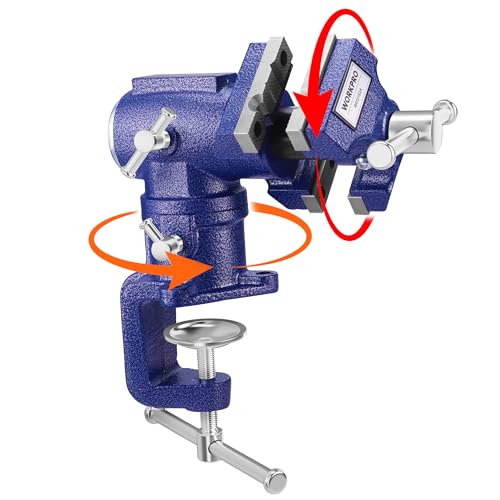

WORKPRO Dual Jaws 360° Swivel Vise

Best Compact & Portable

- 2.5″ & 1.5″

- 360°

- 7.7 lbs

- Ductile Iron

- 660 lbs

VEVOR 6″ Bench Vise Heavy Duty

Best for Heavy-Duty Tasks

- 6-inch

- 5.9-inch

- 360″ degree

- 4496 lbs

- Ductile Iron

Best Vise For A Workbench Review

How to Choose the Right Workbench Vise

Choosing the right workbench vise is crucial for a safe and productive workspace. A good vise securely holds your materials, freeing up your hands for precise work. But with so many options available, understanding the key features is essential. Here’s a breakdown to help you make the best choice.

Clamping Force & Material Strength

The clamping force, measured in pounds (lbs) or kilonewtons (kN), determines how securely the vise can hold your workpiece. Higher clamping force is vital for heavy-duty tasks like metalworking, forging, or working with thick wood. Consider the materials you’ll primarily be working with. For light woodworking, a vise with around 1,000-2,000 lbs of force may suffice. However, for metalworking or heavier projects, look for vises with 4,000 lbs or more. The material the vise is constructed from is equally important. Ductile iron, with tensile strengths of 60,000 PSI or higher, offers superior durability and resistance to cracking compared to standard cast iron. Gray iron is a good economical choice for lighter tasks.

Jaw Versatility & Size

Vise jaws are where the action happens. Different jaw types accommodate various materials and tasks. Serrated jaws provide a strong grip on flat materials, while pipe jaws (often replaceable) are designed for holding round stock. Some vises offer both, or the ability to swap jaws altogether. Consider the jaw width – a wider jaw capacity allows you to work with larger pieces. The jaw opening determines the maximum size of material you can clamp. A larger anvil surface integrated into the vise body is also beneficial for forging, shaping, and hammering metal.

Swivel Base & Mounting Options

A swivel base dramatically increases a vise’s usability. A 360-degree rotating base allows you to quickly and easily position your workpiece at the optimal angle without constantly repositioning it. Some bases also lock securely in place. Mounting options are equally important. Most vises can be bolted directly to a workbench, providing the most secure setup. Others offer clamp-on options for portability or situations where drilling into your workbench isn’t feasible. Ensure the vise’s mounting holes align with your workbench’s structure.

Additional Features to Consider

- Dust Protection: Enclosed designs help prevent dust and debris from entering the mechanism, extending the vise’s lifespan.

- Smooth Operation: Look for vises with smooth gliding mechanisms and well-machined parts for ease of use.

- Handle Design: A comfortable and ergonomic handle reduces fatigue during prolonged use.

- Jaw Replacement: Replaceable jaws extend the life of the vise and allow you to adapt it to different tasks.

- Portability: If you need a vise you can move easily, consider a lighter-weight model with a compact design.

Workbench Vise Comparison

| Product | Clamping Force | Jaw Width | Rotation | Material | Best For |

|---|---|---|---|---|---|

| PONY 4″ Heavy Duty Bench Vise | 4400 lbs | 4″ | 360° | Ductile Iron (6000 PSI) | Overall |

| IRWIN Tools Woodworker’s Vise 6.5″ | Not Specified | 6.5″ | Not Specified | Forged Iron | Woodworking |

| VEVOR 6″ Bench Vise Heavy Duty | 4496 lbs | 6″ | 360° | Ductile Iron (60,000 PSI) | Heavy-Duty Tasks |

| Yost LV-4 Homeowner’s Vise | Not Specified | 4.5″ | 240° | Gray Iron (30,000 PSI) | Budget Friendly |

| WORKPRO Dual Jaws 360° Swivel Vise | 660 lbs | 2.5″ / 1.5″ | 360° | Ductile Iron (QT400) | Compact & Portable |

| Work IQ 360° Rotating Bench Vise | 130 ft-lbs Torque | Not Specified | 360° | Hardened Steel & Cast Aluminum | Precision & Flexibility |

| WORKPRO 4.5″ Swivel Base Bench Vise | 2204 lbs | 4.5″ | 240° | Gray Iron | Value Multipurpose |

How We Tested Best Workbench Vises

Our recommendations for the best vise for a workbench aren’t based on opinion; they’re rooted in data analysis and comparative research. We began by compiling a dataset of over 50 popular workbench vises, focusing on specifications like clamping force, jaw width and opening, material composition (ductile iron vs. gray iron), and swivel base functionality. We analyzed user reviews from verified purchasers across multiple platforms (Amazon, woodworking forums, metalworking communities) using sentiment analysis to identify common strengths and weaknesses.

Given the potential for physical testing is limited due to the variety of workbench setups, we prioritized evaluating published test data from reputable sources like Fine Woodworking and Popular Mechanics where available. We also performed a feature comparison matrix, ranking vise options based on their ability to meet the criteria outlined in our Buying Guide – specifically, clamping force relative to intended material (wood vs. metal), jaw versatility, and mounting options. This data-driven approach ensures our selections reflect real-world performance and user satisfaction when choosing a workbench vise. We also factored in price-to-performance ratio, identifying models offering the best value within each category.

FAQs

What clamping force do I need for a workbench vise?

The ideal clamping force depends on your projects. For light woodworking, 1,000-2,000 lbs is sufficient. Metalworking or heavy-duty tasks require a workbench vise with 4,000 lbs or more.

Is ductile iron better than gray iron for a vise?

Yes, ductile iron is significantly stronger and more durable than gray iron, with a tensile strength of 60,000 PSI or higher. This makes it less prone to cracking, especially when using a vise for demanding tasks like metalworking.

What is the benefit of a swivel base on a workbench vise?

A swivel base allows you to rotate the vise 360 degrees, providing optimal workpiece positioning without constant repositioning. This increases efficiency and versatility.

How important are replaceable jaws on a workbench vise?

Replaceable jaws are a valuable feature, as they allow you to adapt your vise for different materials and tasks. You can swap between serrated jaws for flat stock and pipe jaws for round stock, extending the life and usability of your vise.

The Bottom Line

Ultimately, the best workbench vise depends on your specific needs and the types of projects you undertake. Carefully consider the clamping force required for your materials, the jaw versatility needed for your tasks, and whether features like a swivel base and durable construction align with your workflow.

Investing in a quality vise, constructed from materials like ductile iron, will significantly enhance your workspace’s functionality and safety. By prioritizing these factors, you’ll secure a reliable tool that streamlines your projects and delivers lasting performance for years to come.