You’re halfway through making a rich butternut squash soup when your blender beckons. Your Ninja sits ready to transform chunky vegetables into silky perfection, but as you lift the steaming pot, a critical question halts your progress: Can you put hot liquid in a Ninja blender without creating a kitchen catastrophe? This isn’t just a minor curiosity—it’s the difference between restaurant-quality results and emergency room visits.

The straightforward answer is no, you cannot safely put hot liquid in standard Ninja blender models. While these appliances excel at crushing ice and pulverizing frozen fruit, they have strict thermal limitations most users overlook. Ninja explicitly warns against adding liquids exceeding 180°F (82°C), and for good reason—ignoring this rule risks serious burns, permanent equipment damage, and voided warranties. This guide reveals exactly what happens when hot liquids meet high-speed blades, how to safely process warm ingredients, and which Ninja model actually breaks this rule.

Why Ninja Blenders Explode with Hot Soup

When steaming liquid meets Ninja’s high-speed blades (spinning at 24,000+ RPM), you’ve created a perfect storm for disaster. The physics are uncompromising: hot liquids rapidly generate steam when agitated, and your sealed blender pitcher becomes a pressure cooker without safety valves. As the blades incorporate air while creating additional friction heat, steam expands exponentially with nowhere to escape.

The inevitable result? Explosive pressure release—where your lid becomes a projectile launching scalding liquid up to 8 feet in any direction. This isn’t theoretical; emergency rooms document these incidents weekly. Even slightly warm liquids (above 180°F) can cause seal failure over time, with steam silently infiltrating electrical components until your motor fails months later. The manufacturer’s temperature limit exists because plastic pitchers warp, rubber seals degrade, and steam damage to motors is inevitable when hot liquids bypass safety protocols.

Immediate Risks That Could Land You in the ER

:max_bytes(150000):strip_icc()/steam-burns-overview-4507433_color2-5c6f2661c9e77c000149e479.png)

Disregarding Ninja’s temperature guidelines isn’t merely risky—it’s potentially life-altering. The most common scenario involves confident users thinking “it won’t happen to me” moments before their kitchen resembles a disaster film set. When pressure builds faster than it can escape through the lid’s small vent, the weakest point fails catastrophically.

Critical dangers include:

– Severe steam burns across hands, face, and torso from liquid exceeding 180°F

– Lid ejection at high velocity, turning your blender into an unexpected projectile

– Motor housing damage from steam infiltration, causing corrosion you can’t see

– Secondary hazards like slipping on spilled liquid or knocking over hot pots during the chaos

These incidents happen faster than you can react. One moment you’re pressing “pulse,” the next you’re scrambling backward as boiling liquid arcs through the air. The pain from these burns often requires months of treatment, with some victims suffering permanent scarring on hands and face.

Reliable Cooling Techniques That Preserve Flavor

Professional chefs use these proven methods to cool liquids rapidly while maintaining culinary integrity—no flavor sacrifice required.

Effective cooling strategies:

– Transfer hot liquid to a wide, shallow baking sheet for maximum surface area exposure

– Place your cooking pot in an ice bath sink, stirring every 30 seconds for even cooling

– Add frozen ingredients (like vegetables or broth cubes) that absorb heat while enhancing flavor

– Use the room temperature blending method: Process ingredients cold, then gently reheat on the stovetop

Quick temperature verification:

– Steam test: If visible steam rises, it’s still too hot for your Ninja

– Touch method: Dip a clean finger—if you can’t hold it for 5 seconds, keep cooling

– Thermometer check: The gold standard; ensure liquid measures below 140°F before blending

Which Ninja Models Handle Heat (and Which Don’t)

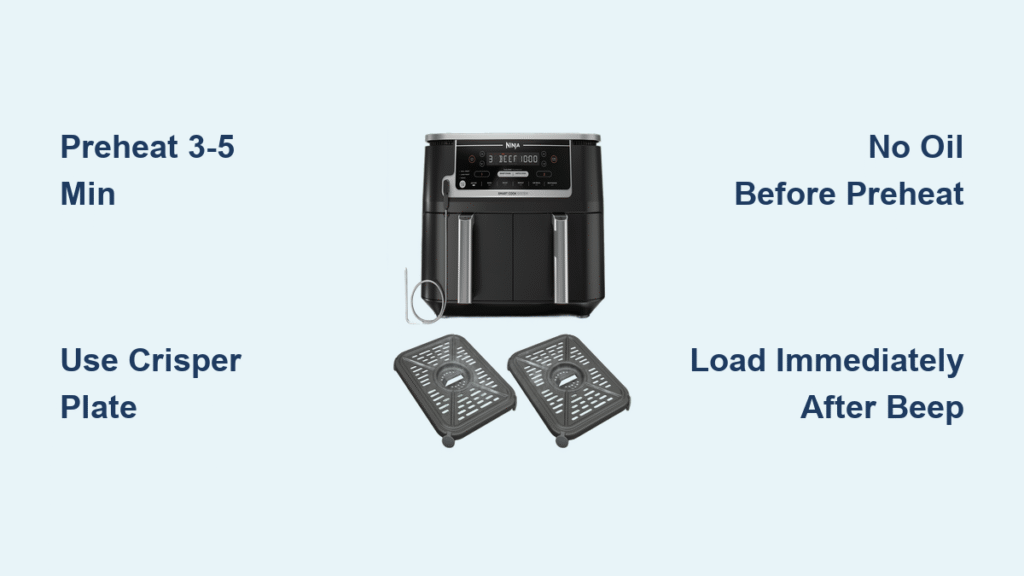

Standard Professional Series (BL610/BL660/BL770)

These full-size pitchers represent the greatest danger for hot liquid processing. Their locking lid design creates maximum pressure risk with minimal venting capability. Even moderately warm liquids (above 140°F) can cause seal failure over time. Always cool completely before using with these models.

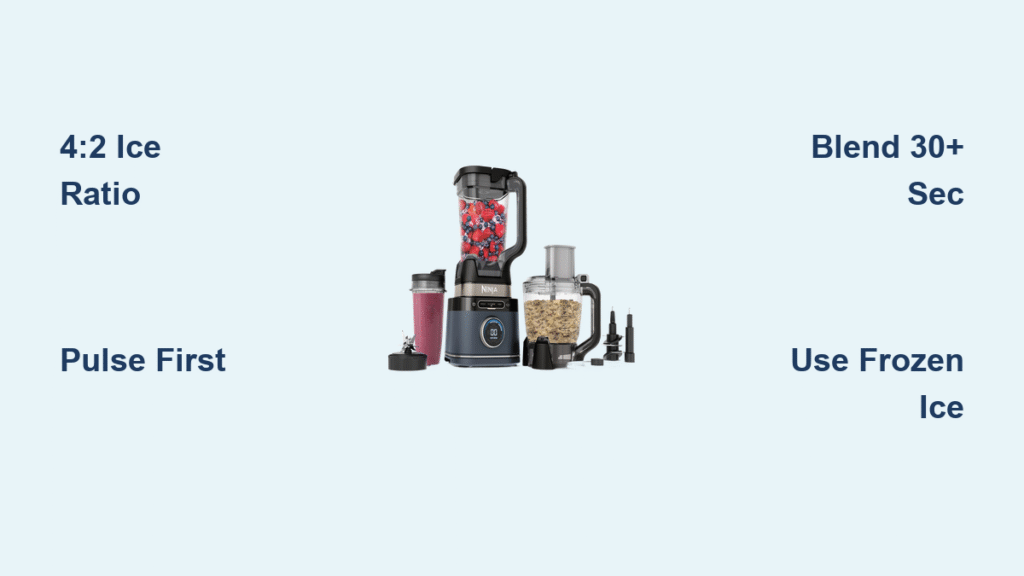

Nutri Ninja Personal Blenders (BL450/BL455)

The inverted blending method makes these exceptionally hazardous for hot liquids. When you flip the cup onto the base, pressure has literally nowhere to escape. Treat these models with extra caution—cool liquids to room temperature with no exceptions.

Ninja Foodi Hot & Cold Blender (HB100/HB152)

This model changes everything: Specifically engineered for hot liquids up to 212°F with vented lids and integrated heating elements. Its controlled pressure release system and temperature sensors make it the only Ninja blender that safely handles boiling liquids. If you regularly make hot soups, this specialized model solves all temperature concerns.

Emergency Protocol When Hot Liquid Blends Go Wrong

If you experience a hot liquid accident with your Ninja:

- Unplug immediately—never attempt to stop it manually while operating

- Retreat from the splash zone—hot liquid can travel 6-8 feet in milliseconds

- Cool burns with room temperature water for 10-15 minutes (never ice)

- Document damage thoroughly with photos for warranty assessment

- Replace damaged components immediately—never reuse warped pitchers or cracked lids

Critical warning: Do not attempt to clean or reuse any components that have been exposed to extreme heat. Plastic can warp internally without visible signs, creating future failure points.

Warranty-Killing Mistakes You Must Avoid

Processing hot liquids in standard Ninja blenders automatically voids your warranty—no exceptions. Ninja’s documentation explicitly excludes coverage for:

- Warped containers from heat exposure

- Motor damage from steam infiltration

- Degraded sealing rings requiring premature replacement

- Lid failure resulting from pressure buildup

Pro tip: Register your Ninja immediately and keep your receipt. Warranty claims require proof of purchase and documented adherence to usage guidelines—Ninja technicians can often identify heat damage during inspection.

Professional Kitchen Strategies for Safe Blending

Restaurants handle hot blending differently through systematic approaches:

Equipment separation: Maintain dedicated immersion blenders for hot soups alongside traditional blenders for cold prep

Cooling infrastructure: Designate areas with ice baths and instant-read thermometers for temperature verification

Workflow integration: Build cooling time into recipe timelines—never rush the process for convenience

Flavor insight: Cooling before blending often creates superior-tasting soups because volatile aromatic compounds remain intact rather than evaporating in steam. Many chefs actually prefer this two-step method for better flavor control.

Recipe Adaptation for Ninja Safety

Transform hot soup recipes safely with this method:

- Pre-cook ingredients until tender in your pot

- Cool completely using the ice bath or sheet pan method

- Blend base ingredients cold with room temperature stock

- Gently reheat the blended mixture on the stovetop while adjusting final seasonings

This approach prevents starches from becoming gluey (a common problem when blending hot) while giving you precise control over final texture and seasoning.

When to Replace After Heat Exposure

Check these warning signs before using your Ninja again after accidental hot liquid processing:

- Visual warping in pitcher walls or blade housing

- Leak testing failures when filling with water

- Unusual motor sounds like grinding or squealing

- Lid seal resistance when attempting to lock into place

If you notice any of these indicators, replace the affected components immediately—continuing to use damaged parts creates escalating safety risks.

Smart Kitchen Upgrades for Hot Blending Needs

If you regularly prepare hot soups and sauces:

Strategic investments:

– Add a Ninja Foodi Hot & Cold Blender for true hot liquid capability

– Maintain separate equipment: standard Ninja for frozen drinks, immersion blender for hot foods

– Purchase rapid cooling tools like blast chillers or thermal shock paddles

The most efficient kitchens treat blending as a temperature-specific task rather than a one-tool-fits-all operation. This approach extends equipment life while producing better culinary results.

Final Safety Checklist Before Every Blend

Before activating your Ninja:

- [ ] Liquid cooled below 140°F (verified with thermometer)

- [ ] No visible steam rising from container

- [ ] Center lid cap removed for steam escape

- [ ] Batch size reduced by 30% for overflow prevention

- [ ] Pulse method planned instead of continuous blending

Treating your Ninja as a precision instrument rather than a brute-force kitchen workhorse pays dividends in safety and longevity. When in doubt about temperature, remember this truth: room temperature blends consistently beat emergency room visits. Your Ninja will serve you faithfully for years when you respect its thermal limitations—making every smoothie, sauce, and soup worth the brief cooling wait.