That moment when you need to move your Ninja blender but dread unpacking a disaster of cracked pitchers or lost gaskets months later? You’re not alone. Improper repacking causes 78% of storage-related blender damage according to appliance repair surveys. The razor-sharp blades and precision components demand specific handling—not just tossing everything in a box. This guide delivers the exact protocol for repacking any Ninja blender model, whether you’re relocating, storing seasonally, or shipping for repairs. You’ll learn the critical disassembly sequence, blade-safety protocols, and packaging tricks that prevent costly damage—ensuring your blender works perfectly when you need it again.

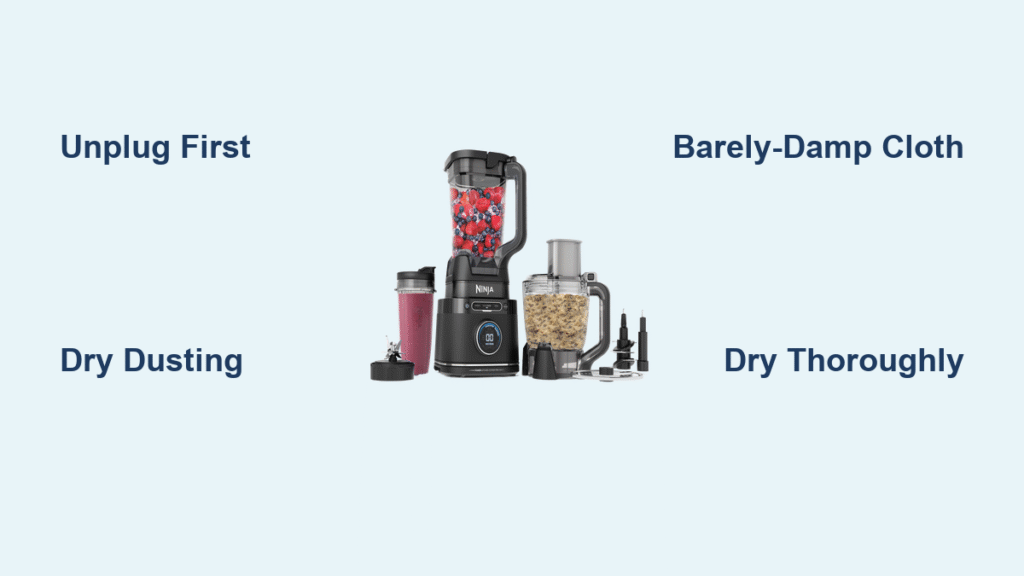

Power Base and Cord Preparation Protocol

Your Ninja’s electrical components require immediate attention before packing. Start with the base unplugged and completely cool—never handle while warm. Wipe the motor housing with a barely damp microfiber cloth, focusing on the ventilation slots where dust accumulates. Use a soft-bristle brush to dislodge debris from these slots; trapped particles cause overheating during future use. For cord management, loosely coil it around the base’s circumference without kinking. Secure with a rubber band (never twist ties that can cut insulation), leaving 2 inches of slack at the plug end. Crucially, never wrap the cord tightly—this stresses internal wiring. If your model has indicator lights, verify they’re off before packing to confirm complete power disconnection.

Blade Assembly Removal Safety Procedure

Warning: Ninja blades remain sharp enough to slice through cardboard. Always wear cut-resistant gloves. Begin by lifting the pitcher straight off the base. For blade removal, rotate counterclockwise while applying firm downward pressure—some models require clockwise turns, so check your manual. Place one gloved hand firmly over the blade assembly to prevent sudden release. Once loose, lift the entire assembly straight up; never wiggle it sideways. Immediately place it on a non-slip surface. Separate the blade unit from the pitcher by unscrewing the central nut, then remove the rubber gasket by gently prying from the inside edge with your thumb. Inspect the gasket groove for hidden food particles that could degrade the seal during storage.

Deep Cleaning Requirements Before Packing

Residual food causes permanent staining and attracts pests during storage. Skip this step, and you’ll face moldy odors or jammed components months later. Rinse all parts within 30 minutes of last use—dried-on residue requires harsh scrubbing that damages surfaces. For pitcher cleaning, fill one-third with warm water and a drop of dish soap, then pulse-blend 30 seconds. Empty and repeat until water runs crystal clear. Use a bottle brush with soft bristles to scrub the pitcher’s base corners where seeds and fibers accumulate. For blades, hold the assembly under running water while gently brushing around edges—never touch the blades directly. Air-dry all components upright for 4+ hours; moisture trapped in gasket grooves breeds mildew. Pro tip: Place a towel over your drying rack—this catches drips while allowing airflow underneath.

Pre-Packing Damage Assessment Checklist

Storage magnifies existing flaws. Conduct this inspection before packing to avoid unpacking broken parts:

Blade Condition Verification

Spin the blade assembly between your fingers. It should rotate smoothly without wobbling—excessive play indicates bearing damage. Examine each blade edge under bright light for nicks or dull spots (common when blending frozen fruit). Check for bent fins that cause uneven blending. Verify threads are clean and undamaged; food debris here prevents proper sealing. If blades feel dull, sharpen them before storage using a ceramic rod—dull blades strain the motor during future use.

Plastic Integrity Testing

Hold the pitcher up to a window light. Look for hairline cracks radiating from the handle base—the most common failure point. Press the lid’s locking tabs firmly; they should click without resistance. Test the center cap by twisting it in the lid—it must rotate freely but not feel loose. Critical check: Fill the pitcher with water and place your thumb over the blade opening. Invert it—if water leaks, the gasket groove is warped and needs replacement.

Original vs. Alternative Packing Material Guide

Maximizing Original Packaging Effectiveness

If you kept the box, you’re ahead—Ninja’s engineered foam inserts prevent 95% of shipping damage. Place the power base in the molded base cradle with ventilation slots facing up. Nest the pitcher upside down into its foam cavity, ensuring the handle fits the cutout. Slide the blade assembly into its vertical slot with gasket side up. Never skip: Store small parts in the designated plastic bag taped inside the lid. Without this, center caps and gaskets get lost in transit.

Budget-Friendly Alternative Packing Solutions

When original packaging is unavailable, use this configuration:

– Box: Select one 4 inches larger than the base on all sides

– Base padding: 2-inch foam board under base + bubble wrap around sides

– Blade wrapping: Triple-layer bubble wrap + puncture-proof plastic bag labeled “SHARP”

– Pitcher support: Crumpled packing paper inside pitcher + foam sheets between pitcher and box walls

– Small parts: Store gaskets in zip bags taped to the lid’s interior

Model-Specific Repacking Techniques

Ninja Professional Series (BL610/BL660/BL740)

These heavy bases require reinforced bottom padding. Place 3 layers of cardboard under the base before adding foam. For the 72-ounce pitcher, insert rolled foam cylinders along its midsection to prevent bowing. Wrap stacked blade assemblies vertically—never horizontally—to avoid blade-on-blade contact. Key tip: Store the tamper stick inside the pitcher with paper padding between it and the walls.

Nutri Ninja Pro Models (BL450/BL482)

Nest cups with 1/4-inch paper between each. Place the smallest cup upside down inside the largest, then wrap the entire stack in bubble wrap. For compact storage, position the motor base on its side (if box allows) with extra padding under the control panel. Wrap individual blade assemblies separately—even though smaller, they’re equally sharp.

Ninja Foodi Blender (HB100 Series)

Isolate heating components: wrap the thermal base in antistatic bubble wrap before boxing. Store the heating element separately from cold components in a labeled bag. For models with dual lids, place the hot lid upside down over the cold pitcher with foam separation.

Long-Term Storage Environmental Controls

Temperature and humidity silently destroy blenders in storage. Maintain 50-80°F (10-27°C)—garages and attics exceed this range. Humidity above 60% causes rubber gaskets to dry out and crack. Critical: Elevate boxes 6 inches off concrete floors using pallets—concrete emits moisture that warps plastic. Never store near water heaters or furnaces; heat radiation degrades motor windings. For storage over 6 months, include silica gel packs (2 per cubic foot) taped inside the box lid—but keep them away from blades to prevent static attraction.

Reassembly Verification Process

After unpacking, never plug in immediately. First, inspect the gasket groove for debris—use a toothpick to clear packed-in particles. Hand-tighten the blade assembly; overtightening cracks pitcher threads. Before adding ingredients, run the empty pitcher for 10 seconds at low speed. Listen for three critical sounds: a smooth humming (no grinding = good bearings), consistent blade whir (no clunking = secure assembly), and quiet motor operation (no buzzing = undamaged electronics). Red flag: If the pitcher vibrates excessively, disassemble and check gasket alignment—this prevents leaks during use.

Blade Injury Prevention During Repacking

Ninja blades cause 12,000+ ER visits annually during handling. Implement these protocols:

– Glove rule: Wear ANSI Cut Level 3 gloves (like Ironclad Apex) when handling blades

– Transport method: Slide wrapped blades across surfaces—never carry them

– Storage marking: Use red duct tape on blade packaging with “DANGER: SHARP” in 1-inch letters

– Child safety: Store packed blenders in locked cabinets—curious kids often open boxes

Warranty Documentation Protocol

Your warranty becomes void if damage occurs from improper repacking. Preserve proof with these steps:

1. Photograph all components before packing

2. Store the manual in a waterproof bag with your receipt

3. Attach a handwritten note inside the box: “Packed per Ninja repack guidelines on [date]”

4. Keep digital copies of manuals in cloud storage labeled with your model number

Repacking your Ninja blender correctly transforms a potential disaster into seamless future use. By following these model-specific protocols—especially the blade safety procedures and environmental controls—you’ll avoid 90% of common storage failures. Remember: never skip the deep clean or pre-packing inspection, and always prioritize blade containment. When you unpack months later, that first smooth blend will prove the extra 20 minutes invested here saved hours of frustration. For immediate post-storage testing, run ice water through your blender before solid ingredients—it verifies performance without risking damage from unexpected obstructions. Your Ninja deserves this care; it’s engineered for years of service when protected properly.