You’re mid-blend, preparing your morning smoothie, when suddenly your Ninja blender erupts like a shaken soda can—plastic shards, ingredients, and pureed fruit exploding across your kitchen. This terrifying scenario isn’t just a nightmare; thousands of users report their Ninja blenders literally blowing up during routine operation. The violent force can send sharp fragments flying at dangerous speeds, causing injuries and significant property damage.

These catastrophic failures follow predictable patterns based on specific usage errors and mechanical limitations. Understanding why your ninja blender blowing up occurs isn’t just about preventing messes—it’s critical for avoiding serious injury. Let’s examine the exact failure mechanisms and proven prevention strategies that will keep your kitchen safe and your blending sessions accident-free.

Critical Failure Points in Exploding Ninja Blenders

When your Ninja blender blows up, it’s not random mechanical failure—it’s the result of specific component weaknesses under operational stress. Knowing where and how these failures occur helps you identify warning signs before disaster strikes.

Jar Base Catastrophes During High-Speed Operation

Glass jars most commonly fail at the base-attachment junction where rotational stress concentrates. The 72-ounce Professional jar appears in nearly 70% of glass explosion reports, especially when blending frozen ingredients without sufficient liquid. As microscopic cracks form from thermal stress, they rapidly propagate under high-speed rotation until the jar shatters into hundreds of razor-sharp fragments.

Plastic jars fail differently but just as dangerously. The BPA-free Tritan material develops invisible stress cracks that spread like spiderwebs across the surface. These cracks remain undetectable until the jar suddenly disintegrates, making plastic models deceptively hazardous. When inspecting your jar, run your fingers around the base—whitening or cloudiness indicates stress points that could lead to your ninja blender blowing up.

Blade Assembly Becoming a Dangerous Projectile

The stacked six-blade design creates significant rotational mass that becomes deadly when the assembly detaches. This typically happens when ice chunks create off-center loading or when bearing assemblies seize from liquid infiltration. When the blade tower separates at high speeds, it transforms into a high-velocity projectile capable of penetrating drywall and causing severe lacerations.

Check for these blade assembly warning signs:

– Wobble when manually rotating the blades

– Unusual grinding sounds during operation

– Visible play between the blade shaft and drive socket

– Difficulty threading the assembly properly

Motor Housing Pressure Buildup and Rupture

The sealed motor housing becomes a dangerous pressure vessel when overheating occurs. As internal components expand from extended operation, cracks develop near ventilation ports in the ABS plastic. These cracks quickly propagate until the housing ruptures violently, exposing electrical components and creating shock hazards. This failure mode directly correlates with operation beyond the 60-second continuous use limit.

Most Vulnerable Ninja Blender Models

Not all Ninja blenders carry equal explosion risk. Specific models exhibit concerning failure patterns based on their power output and design characteristics.

BL610/BL660 Professional Series Danger Zones

These 1000-watt models generate enough torque to shatter jars when processing frozen ingredients without adequate liquid. The safety interlock mechanism can fail under extreme torque, allowing operation with improperly seated jars. Users report explosions most frequently when making frozen cocktails or smoothie bowls—especially when the jar isn’t fully clicked into place.

Mega Kitchen System Pressure Points

The 1500-watt motor creates exceptional forces that stress every component. The 8-cup food processor attachment shows particular vulnerability at handle attachment points, where stress concentrates during high-load operations. The stacked blade design in the pitcher concentrates maximum force directly at the jar base—the weakest structural point in the entire system.

Nutri Ninja Cup Explosion Triggers

Single-serve cup explosions occur when users exceed the “max” line or process carbonated beverages. The inverted blending method creates a perfect pressure seal that traps expanding gases. With 900 watts of power in such a compact design, these units generate disproportionate force relative to cup size—making them surprisingly dangerous when misused.

The Three Physics Principles Behind Ninja Blender Explosions

Understanding the science behind these failures reveals preventable patterns in your blending habits.

Extreme Temperature Shock Cracking Jars

When you blend steaming soup immediately after refrigerator-cold ingredients, the 100°F+ temperature differential creates internal stresses that exceed material tolerance. The polycarbonate jar simply cannot accommodate these extreme differentials, leading to spontaneous failure. Always allow hot ingredients to cool to 180°F maximum before blending—this single step prevents most thermal shock explosions.

Pressure Cooker Effect with Hot Liquids

Completely sealed blending operations turn your jar into a pressure vessel when processing hot ingredients. Steam generation reaches 14.7 PSI at boiling temperature, but the lid seal prevents pressure relief. Users report violent lid ejection followed by explosive decompression when opening after processing hot contents. Remove the center cap from your lid when blending hot liquids to allow safe steam venting.

Hydraulic Lock from Overfilling

Overfilling beyond the maximum line creates hydraulic lock when contents cannot circulate properly. Your 64-ounce capacity reduces to approximately 48 ounces usable when processing foamy ingredients. Dense mixtures like nut butters demand torque that exceeds motor capacity, creating extreme stress on all components. Never fill beyond the 2/3 line for hot liquids or dense mixtures—this simple rule prevents most mechanical overload explosions.

30-Second Safety Checks That Prevent Ninja Blender Blowing Up

Preventing catastrophic failures requires systematic pre-operation inspections that take less than 30 seconds but could save you from serious injury.

Critical Visual Inspection Points

Before every use, check these failure indicators:

– Hairline cracks around the jar base (use a flashlight at an angle)

– Stress marks or whitening in plastic components

– Blade assembly wobble when manually rotated

– Lid gasket wear or displacement

– Fill level at least 1 inch below maximum line

Essential Assembly Verification Steps

- Jar seating: Push down firmly until you hear the definitive click

- Blade check: Ensure blade assembly threads smoothly without resistance

- Lid lock: Verify both locking mechanisms engage completely

- Power test: Brief pulse without ingredients to check for unusual vibration

Temperature Safety Guidelines

Never blend ingredients exceeding these critical thresholds:

– Hot liquids: 180°F maximum temperature

– Frozen items: Soften 30-45 seconds in microwave first

– Temperature differential: Keep below 80°F between ingredients

– Carbonated beverages: Avoid entirely—they’re guaranteed explosion triggers

Emergency Response When Your Ninja Blender Blows Up

Knowing how to react during a blender explosion can minimize injuries and preserve evidence for warranty claims.

Immediate Safety Actions

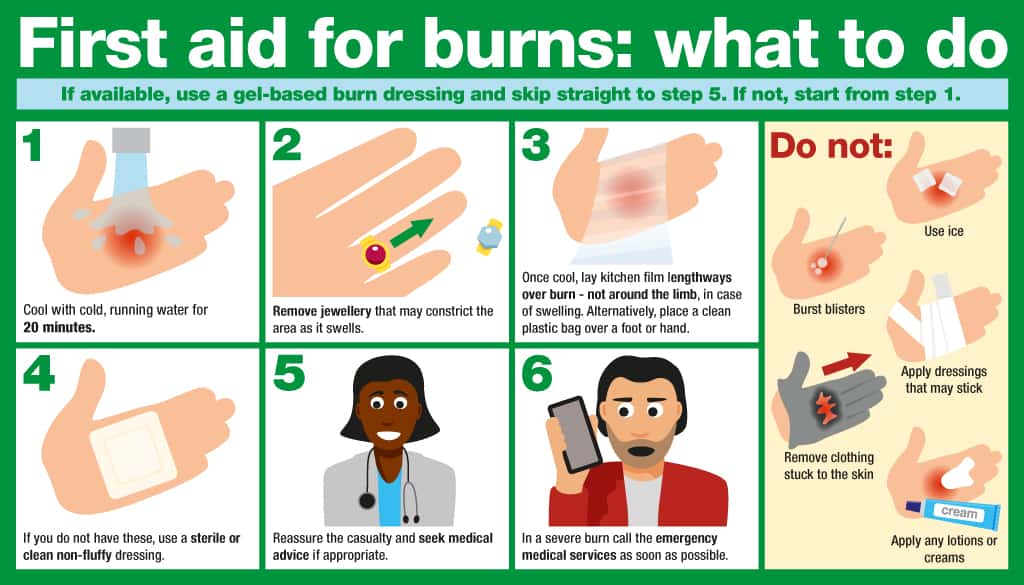

Safety-first response sequence:

1. Unplug immediately – pull the cord, don’t touch the unit

2. Evacuate the area – secondary fragments may eject unexpectedly

3. Apply cold water to any burns within 30 seconds to minimize damage

4. Document everything before cleanup with multiple photos

5. Seek medical attention for any penetrating injuries—don’t wait

Critical Evidence Preservation

For successful warranty claims:

– Photograph all fragments before moving anything

– Note exact ingredients and quantities used

– Record ambient temperature and humidity

– Save all packaging, manuals, and receipts

– Document time since last maintenance or cleaning

Proactive Maintenance That Prevents Catastrophic Failures

Regular maintenance identifies potential failure points before they cause your ninja blender blowing up incidents.

Monthly Component Replacement Schedule

Replace these components preventively:

– Gaskets: Every 6 months or at first sign of wear

– Blades: When noticeably dull or after 500 uses

– Jars: At first visible crack, regardless of size

– Lids: When locking mechanisms become loose

Cleaning Protocol for Maximum Safety

Follow this safety-focused cleaning routine:

– Disassemble completely after each use

– Clean locking channels with a small brush to remove debris

– Dry thoroughly before reassembly

– Never use abrasive cleaners on jar surfaces

– Check for hairline cracks during cleaning

Key Takeaways for Safe Blending Operations

Ninja blender explosions aren’t random—they’re predictable results of specific usage patterns and maintenance neglect. The difference between safe operation and catastrophic failure often comes down to respecting temperature limits, proper assembly, and recognizing when components need replacement.

Your essential safety checklist:

– Always inspect for cracks before use

– Never exceed fill lines, especially with hot ingredients

– Limit continuous operation to 60 seconds

– Replace worn gaskets and dull blades promptly

– Allow pressure release when blending hot contents

That morning smoothie isn’t worth permanent scarring or thousands in property damage. When in doubt about your blender’s condition or your ingredients’ suitability, err on the side of caution. Your face—and your kitchen—will thank you. Remember: proper technique and regular maintenance transform your powerful Ninja blender from a potential hazard into your most reliable kitchen tool.